Please note that some of the links on this website are affiliate links. I will earn a commission if you decide to make a purchase after clicking through the link. As an Amazon Associate I earn from qualifying purchases.

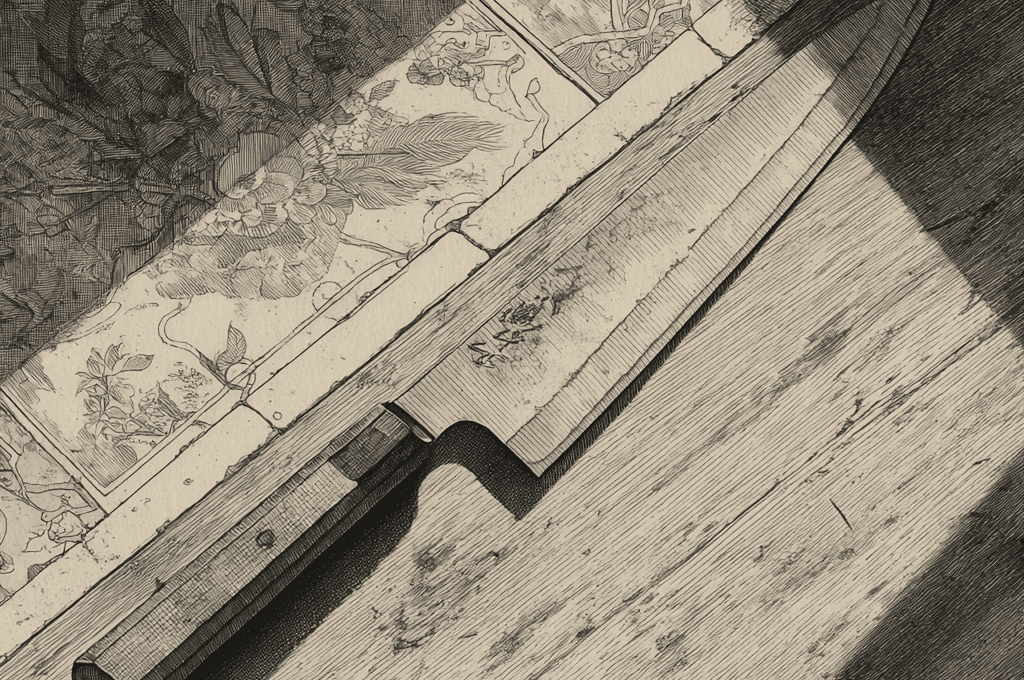

Why Chefs Are Paying Attention to a New Generation of Japanese Knife Makers

Best Chef Recipes — Tools & Technique

Japanese knife culture continues to evolve. Alongside established brands and legacy workshops, a new generation of makers is producing knives that better reflect the realities of modern professional kitchens—long prep hours, precise ingredient handling, and the need for tools that perform consistently rather than impress visually.

The makers listed below are gaining recognition among working chefs, sharpeners, and serious knife users for their attention to grind geometry, steel treatment, balance, and long-term usability. This is not a collector’s list. These are knives chosen to work.

Yu Kurosaki (Echizen, Fukui)

Part of the Takefu Knife Village collective, Yu Kurosaki represents a new generation of independent blacksmiths working within a traditional framework. His knives are known for consistent heat treatment, refined grinds, and reliable edge retention.

Takefu Knife Village ·

Yu Kurosaki at Chubo Knives

Shiro Kamo (Echizen, Fukui)

Shiro Kamo produces thin, high-performance blades with an emphasis on cutting efficiency and control. His work prioritizes sharpness and precision over ornamentation.

Shiro Kamo at Chef Knives To Go

Yoshikane Hamono (Sanjo, Niigata)

Yoshikane blends traditional Sanjo forging methods with modern knife profiles. Their blades are recognized for controlled distal taper, smooth food release, and predictable sharpening behavior.

Yoshikane Hamono (Official) ·

Yoshikane at Carbon Knife Co.

Takayuki Shibata (Shibata Knives, Hiroshima)

Shibata’s knives are designed with professional kitchens in mind, emphasizing thinness, balance, and efficiency. Developed with chef input, his blades are optimized for speed and accuracy.

Wakui (Sanjo, Niigata)

Wakui knives are gaining attention for understated design and strong performance at a practical price point. Known for solid heat treatment and comfortable profiles.

Hado (Sakai, Osaka)

Hado is a newer Sakai-based brand working closely with skilled blacksmiths and sharpeners. Their knives reflect Sakai’s long knife-making tradition while addressing contemporary preferences for lighter blades.

Nakagawa Hamono (Sakai, Osaka)

Nakagawa produces finely ground blades with careful attention to sharpening characteristics and steel selection.

Karaku (Tosa, Kochi)

Forged in Tosa, Karaku knives emphasize durability and function. Often finished in kurouchi with straightforward profiles suited for demanding prep environments.

Akira-Saku (Japan)

Akira-Saku knives are hand-forged with a deliberately rustic approach, favoring carbon steel performance and visible craftsmanship.

Takamura Cutlery (Echizen, Fukui)

While not a single artisan, Takamura remains an important contemporary producer. Their knives are known for thin grinds, precise steel treatment, and high cutting performance.

Why These Makers Matter to Chefs

These makers are responding directly to professional needs: lighter tools, improved balance, predictable sharpening, and durability under constant use. Their work reflects a shift away from ornamental excess toward functional refinement.

For chefs, choosing a knife from one of these makers is less about trend and more about trust—trust that the blade will perform consistently, sharpen cleanly, and improve with use over time.